In this article we will show the advantages and disadvantages of printing methods. DTF, DTG, sublimation and screen printing methods.

Diyinkjet will not go into depth comparing the advantages and disadvantages of DTF, DTG, sublimation and screen printing methods. Each printing method has an outstanding advantage, the choice of which printing method depends on many factors.

The advantages and disadvantages of printing methods, will talk about printing on fabrics mainly. But we will still cover other materials that DTF, sublimation, dtg and silkscreen printing methods can print.

I: Advantages and disadvantages of DTF printing

What is DTF printing?

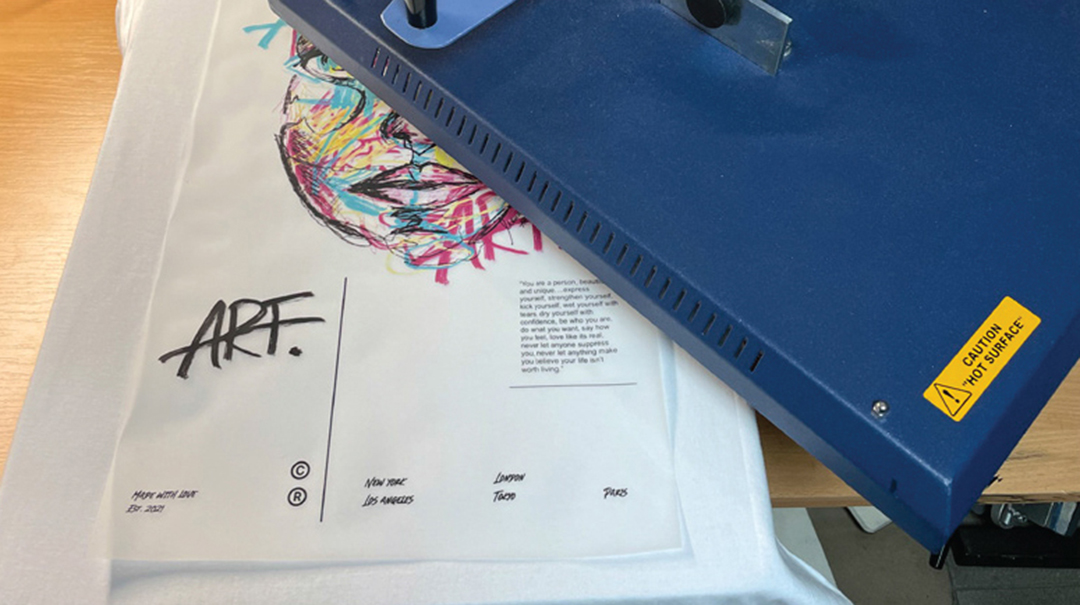

Print DTF or Direct To Film. As the name implies, Direct to Film printing is a process of printing images onto Film, which is then transferred onto fabric. and supported by the temperature and pressure of the press.

What makes DTF printing stand out is that it can print on any fabric, and there is no color limit. Images printed on film are supported by inkjet printers, so there is no limit to colors and lines.

you can see DTF Printing Guide For Beginners

In this article diyinkjet will give the Advantages and disadvantages of DTF printing, sublimation printing, dtg printing and silkscreen printing.

Advantages and disadvantages of DTF printing

Advantages of DTF printing

- Works with almost all types of fabrics

- Does not require pre-treatment of the fabric

- Faster process time and less tedious than DTG printing

- Printed designs exhibit good wash and rub characteristics

- Different properties of printed design with different hot melt powder

- Cost-effective DTF printing process

- Easy DTF printing manual

- No cracking when stretching the printed design

- Prints can be stored and heat pressed later

- DTF printer can be upgraded to be more automatic

Disadvantages of DTF printing

- Color may differ when printed (can be enhanced by adjustment in RIP software)

- White color can be tricky to use/ maintain (You can see a solution to prevent printhead clogging and white ink management here)

II: Advantages and disadvantages of sublimation printing

What is Sublimation Printing?

Sublimation is a scientific term, which is a direct transition of matter from the solid state to the gaseous state, without going through the liquid state. it occurs only at specific temperature and pressure.

So sublimation printing is the transition of the state of the print on paper from the solid state to the gaseous state, under the influence of temperature and pressure. The print will be transferred to the product to be printed by sublimation.

Advantages and disadvantages of sublimation printing

Advantages of sublimation printing

- As a method that allows you to print on hard surfaces such as ceramic, metal (provided that the surface has been treated for sublimation printing).

- Sublimation printing technique is relatively simple, you can master the sublimation printing process in a short time

- Sublimation printing is supported by inkjet printers, on sublimation paper. So there will be unlimited colors

- The cost for the prints is the same. You can print 1 or 10000 prints. cost is the same

- The printing ink after sublimation is mixed into the substrate, so it has high color fastness

- Print time is fast, so you can produce your order in a few hours

- Cost to buy cheap printers and presses

Disadvantages of sublimation printing

- You can only print on 100% polyester or 2/3 polyester fabric

- You can only print on white fabric, hard surfaces like ceramic, metal need surface treatment for sublimation printing

- Colors can be difficult to adjust due to temperature effects, after a while you can master the colors.

III: Advantages and disadvantages of DTG printing

What is DTG printing?

DTG stands for “Direct to Garment Printer”. As the name implies, the image to be printed will be printed directly onto the fabric, thanks to an inkjet printer.

Advantages and disadvantages of DTG printing

Advantages of DTG printing

- Set up to print a product quickly

- Unlimited colors or images

- Can make small quantity orders quickly

- Printed designs with exact dimensions

- The cost for the prints is the same. You can print 1 or 10000 prints. cost is the same

- It is possible to print on dark fabrics, thanks to the use of white ink, printed below

Disadvantages of DTG printing

- Can only print on cotton fabric, at least 80% cotton. Cannot print on polyester fabric

- Some printers cannot print in white.

- White ink can be difficult to manage, as white ink clogs the printhead. (You can see Automatic Printhead Cleaning And White Ink Management)

IV: Advantages and disadvantages of screen printing

What is silkscreen printing?

Simply put, silkscreen printing is a printing technique that uses a printing mold. on the printing die that has positioned the print on it.

There will be an ink lever, to push the ink evenly onto the surface of the printing mold. Through the small holes on the surface of the mold, the ink will go down the surface to be printed.

Advantages and disadvantages of screen printing

Advantages of silkscreen printing

- High color fastness

- Flexibility in materials. can print on many different materials (print on glass, print on metal, print on fabric, print on plastic, etc.)

- No size limit

- Can print in large quantities at low cost

- Easy to master printing technology

Disadvantages of screen printing

- High cost for small print volume. Because the cost to make the printing mold is high

- Time to set up for a high silk print

- Limited by color. not compatible with gradient color

- If too many colors, silkscreen printing will be expensive

- Cannot print with small details

These are the advantages and disadvantages of DTF printing, DTG printing, Sublimation printing, and screen printing. Each printing method has a prominent advantage and holds an important position.

Which printing method to choose depends on the requirements for your product, and other factors such as finances, the number of orders you have, etc.

Nowadays, owning a DTG printer or a DTF printer at a low cost is easy. You can also make your own DTG or DTF printer. Therefore, the choice of printing method is completely dependent on the requirements for your product.

Learn about 2 color systems RGB and CMYK

Epson Printhead Technology

Compare thermal bubble jet print head and piezo electrically actuated inkjet printhead

Cause Printer clogged printhead? How To Treat It Thoroughly

Advantages and disadvantages of DTF, sublimation, dtg and silkscreen printing methods

Learn about 2 color systems RGB and CMYK

Epson Printhead Technology

Compare thermal bubble jet print head and piezo electrically actuated inkjet printhead

Cause Printer clogged printhead? How To Treat It Thoroughly

Advantages and disadvantages of DTF, sublimation, dtg and silkscreen printing methods

Learn about 2 color systems RGB and CMYK

Epson Printhead Technology

Compare thermal bubble jet print head and piezo electrically actuated inkjet printhead

Cause Printer clogged printhead? How To Treat It Thoroughly

Advantages and disadvantages of DTF, sublimation, dtg and silkscreen printing methods