Causes and ways to fix the printer’s clogged printhead

In the long-term use of any machine, it is inevitable that there will be errors when using it, especially with printers that use white ink such as UV printers, DTG printers, DTF printers. frequently clogged printhead. This is the most basic and common mistake that affects the quality of the finished product. Therefore, finding the cause and fixing the error quickly is always the top concern.

1. The printer has a clogged printhead due to ink

1.1 Due to dry ink, deposited in the print head

Cause: Inkjet printers use an ink that is a liquid, when it evaporates, a layer of color remains on the material. When printing, a small amount of ink remains and remains at the printhead, this ink will quickly dry out after many printings, after many days, the amount of ink deposited becomes thicker and thicker, gradually shrinking the nozzle and clogged printhead. Usually, after using the machine, we only clean the outside of the spray hole without paying attention that cleaning the inside of the nozzle is a matter of concern.

Fix: When there is a problem that the nozzle is blocked due to the accumulation of dry ink, you need to use the nozzle cleaning function to push out the excess dry ink. However, this method consumes a lot of ink, so after each use, you should clean the nozzle not only outside but also inside the nozzle.

1.2 Due to deposition of white ink causing clogged printhead

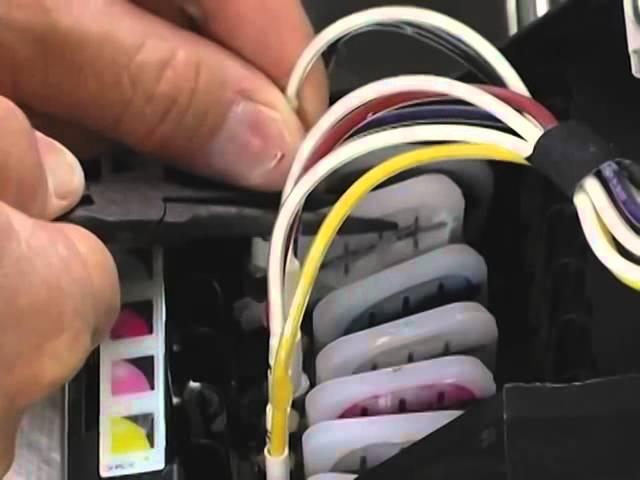

Cause: with white ink of UV printers, DTG printers and DTF printers, White pigments tend to deposit (go below solvent). so it is easy to clog the nozzles of the printhead. with conventional white ink management systems that can only prevent white ink deposition on the outside of the print head. which cannot prevent printhead clogging.

Fix: you need to suck the white ink in the print head out, every time you don’t use the printer for a long time (about 12 hours).

In addition you can also use our automatic printhead cleaning system, and intelligent white ink management. automatic printhead cleaning

1.3 Due to ink problems

Cause: Currently there are many different types of printing inks, some of which are because the factory uses too much drying chemicals in the ink, causing the ink to dry faster than usual. As a result, the printer is clogged with the nozzle because the ink dries too quickly, which narrows the nozzle and causes clogged printhead. When an error occurs, you can clear the nozzle easily, but the dry ink will cause this situation to repeat continuously, interrupting the work. Moreover, when used for a long time, the nozzle clogging condition persists, affecting the work and consuming ink each time the inkjet print head is opened.

In addition, you also need to pay attention to the expiration date of the ink.

Fix: change to quality ink, with proper ink drying capacity to overcome the problem of ink drying quickly while printing.

1.4 Changing ink often clogs nozzles

Cause: in some cases, changing the ink too often but not maintaining the printhead well, will affect the operation of the nozzle and cause the clogged printhead. This cause is usually less common but has a significant impact on the operation of the printhead.

Fix: maintain regular printhead maintenance and limit changing ink too often.

1.5 Abnormal ink adhesion

Cause: the stickiness of the ink is too high or too low, which will cause the clogged printhead. The stickiness of the ink determines the fluidity of the ink, the higher the stickiness, the lower the fluidity. Ink that is too liquid will cause air to be drawn in, causing the voltage crystals to not absorb the ink, but all air, the nozzle will not eject ink. When the temperature is low, the ink stickiness will be high and vice versa, the use of two types of ink with temperature difference and stickiness is the cause of the ink jetting.

How to fix: clean the nozzle, take out the ink and adjust the temperature to the appropriate level, usually from 22-25 degrees Celsius. Usually to avoid this situation you should leave the ink in the environment to be used for a little while. at least 24 hours before use.

To fix the error caused by abnormal ink stickiness, you need to take out the ink cartridge to adjust the temperature.

2. Inkjet printer clogged due to crystal card

2.1 Due to damaged piezoelectric crystal card

Normally, the crystal card can only be used for 1 year, if the machine is used regularly with high intensity, the crystal card will be damaged faster, so it may not be used for up to 1 year. The only way to fix it is to replace the card with a new one.

2.2 Due to the piezoelectric crystal card overload

When printing, if the ink jet nozzle is uneven, especially when you need to print in bold color mode, you need to spray a lot of ink, the nozzle will be blocked, the ink will be out unevenly, causing the product to be of poor quality. The best way to fix this error is to replace a new, better quality nozzle.

3. The filter mesh inside the nozzle is clogged

Cause: this is also a fairly common condition that causes the print head to become clogged, preventing ink from being ejected. The reason is that the machine does not regularly operate, the ink is not mobile for a long time, which will make the ink easily stick to the filter screen as well as the walls of the nozzle. This reduces the circulation area of the ink, causing the filter to gradually become sealed, the nozzle does not spray out ink.

How to fix: clean the entire nozzle, including the filter inside, note that the machine must be cleaned after every day of use, and maintained the nozzle periodically to avoid ink blockage, especially for The machines at the enterprise have low working intensity.

How to clean and maintain the nozzle to avoid clogged printhead

How to clean a clogged inkjet printhead

Cleaning the nozzle every time it is clogged is the best and fastest way to solve the printer problem. Specifically, when detecting a clogged nozzle, you need to find out the cause and handle the inkjet printhead as follows:

For mild ink blockage:

you need to pause the operation of the machine, use the suction device to suck out the ink at the nozzle, then proceed to clean. Finally, use the water pump cylinder to wash away the remaining ink on the nozzle.

In case of serious inkjet printhead blockage:

You need to clean the inkjet printhead more thoroughly, by removing the nozzle from the nozzle assembly. Use specialized washing water to put in a clean cup or glass to soak the nozzle, note that the height of the water is only 2-3mm, do not let the upper part of the connector touch the water or it will be damaged. Then cover with cling film to prevent dust from entering and leave overnight.

After soaking, take out the nozzle, use a specialized washing device to create vibrations for the nozzle, change a new cup of specialized washing water to put the nozzle in, use the washing device to wash the nozzle for about 5 minute. Note that the amount of water is still no more than 2-3mm and do not wash for longer than 5 minutes.

Finally, use a syringe to inject 40ml of specialized washing water and press it into the ink supply connector on the nozzle. If the water coming out of the nozzle has a straight line, it shows that the nozzle has been washed, otherwise you need to repeat the above steps until the water flows out in a straight line, the nozzle will work properly.

How to properly maintain the printhead

With any type of machine whether UV printer, DTG printer or DTF printer. Proper maintenance of the nozzle is always the best solution to prevent the nozzle from being blocked when in use, to avoid hindering the work, and affecting the quality of the finished product when printing. To maintain the best and most effective nozzles, you need to do the following:

Maintenance of inkjet print head after every working day

- Turn off the power, then use a cleaning gauze soaked in specialized washing water.

- Move the nozzle array towards the ink discharge, then use a gauze pad to seal the nozzle of the machine, keep it like that until the next working day.

Maintenance of inkjet printheads when not in use for the next 24 hours

- Turn off the power of the machine, then move the nozzle to the washing area, below the nozzle should put a cup, porcelain or stainless steel cup to be able to store washing water.

- Empty the toner in the auxiliary cartridge and use washing water to clean it

- Remove the ink pipe on the nozzle and use the washing water pump cylinder to clean the nozzle. Then use the device to dry the washing water in the nozzle, but leave a small amount of water to keep the nozzle moist.

- After being cleaned, the nozzle is put into a clean container, sealed with plastic film, can be stored for about 1 month without damaging the nozzle, causing ink blockage when used.

Automatic printhead cleaning maintenance.

you can refer to the automatic printhead cleaning system, during the time when the printer is not in use. it is compatible with epson A4, A3 and A2 printers. In addition, we can also customize it for different types of printers. You can set a timer for the system to clean the printhead automatically. Make sure that the ink does not dry in the print head.

Learn about 2 color systems RGB and CMYK

Epson Printhead Technology

Compare thermal bubble jet print head and piezo electrically actuated inkjet printhead

Cause Printer clogged printhead? How To Treat It Thoroughly

Advantages and disadvantages of DTF, sublimation, dtg and silkscreen printing methods

Learn about 2 color systems RGB and CMYK

Epson Printhead Technology

Compare thermal bubble jet print head and piezo electrically actuated inkjet printhead

Cause Printer clogged printhead? How To Treat It Thoroughly

Advantages and disadvantages of DTF, sublimation, dtg and silkscreen printing methods

Learn about 2 color systems RGB and CMYK

Epson Printhead Technology

Compare thermal bubble jet print head and piezo electrically actuated inkjet printhead

Cause Printer clogged printhead? How To Treat It Thoroughly

Advantages and disadvantages of DTF, sublimation, dtg and silkscreen printing methods