-

×

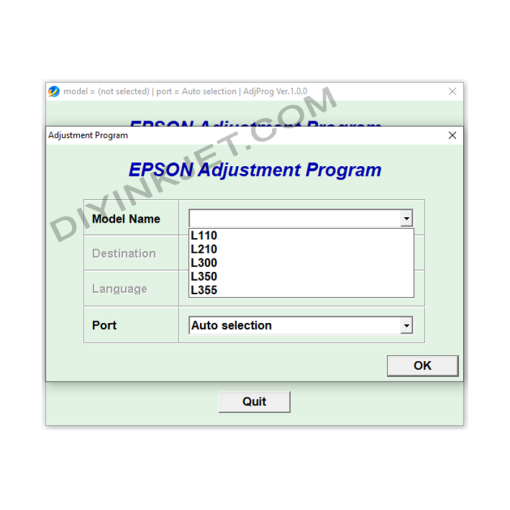

Epson L110 L210 L300 L350 L355 Adjustment Program

2 × 5 $

Epson L110 L210 L300 L350 L355 Adjustment Program

2 × 5 $ -

×

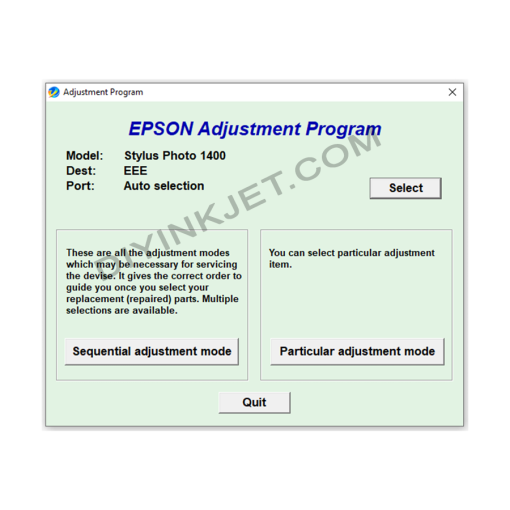

Epson Stylus Photo 1400 Adjustment Program

1 × 5 $

Epson Stylus Photo 1400 Adjustment Program

1 × 5 $ -

×

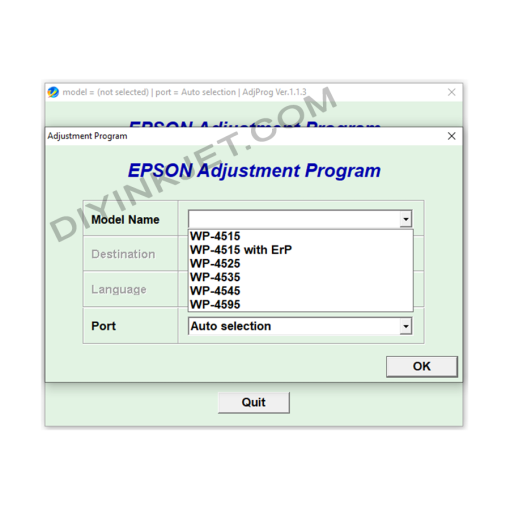

Epson WF-4515 WF-4525 WF-4535 WF-4545 WF-4595 Adjustment Program

1 × 5 $

Epson WF-4515 WF-4525 WF-4535 WF-4545 WF-4595 Adjustment Program

1 × 5 $ -

×

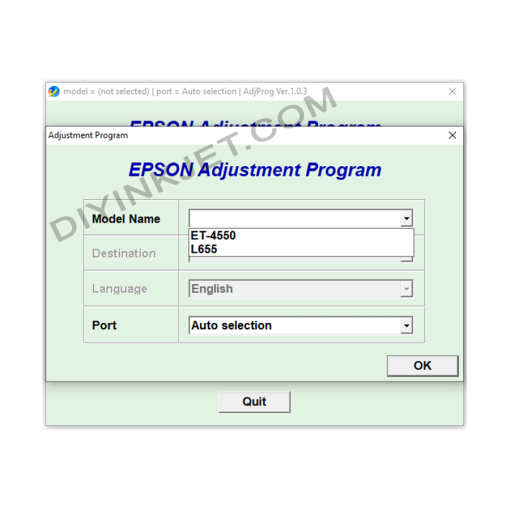

Epson ET-4550 L655 Adjustment Program

1 × 5 $

Epson ET-4550 L655 Adjustment Program

1 × 5 $ -

×

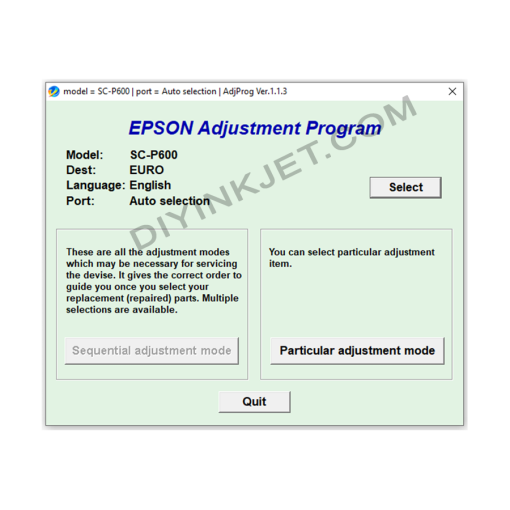

Epson Sure Color P600 Adjustment Program

2 × 5 $

Epson Sure Color P600 Adjustment Program

2 × 5 $ -

×

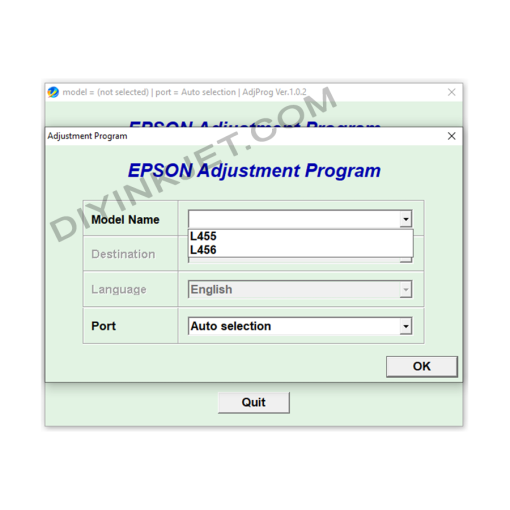

Epson L455 L456 Adjustment Program

2 × 5 $

Epson L455 L456 Adjustment Program

2 × 5 $ -

×

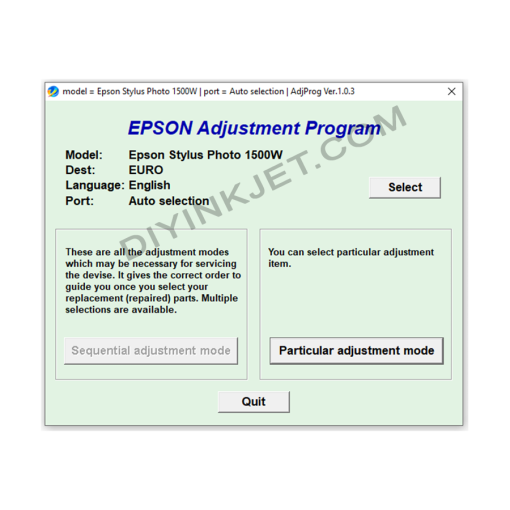

Epson Stylus Photo 1500W Adjustment Program

1 × 5 $

Epson Stylus Photo 1500W Adjustment Program

1 × 5 $ -

×

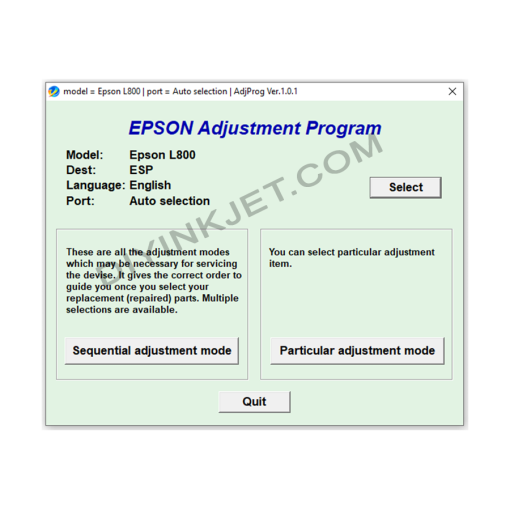

Epson L800 Adjustment Program

1 × 5 $

Epson L800 Adjustment Program

1 × 5 $ -

×

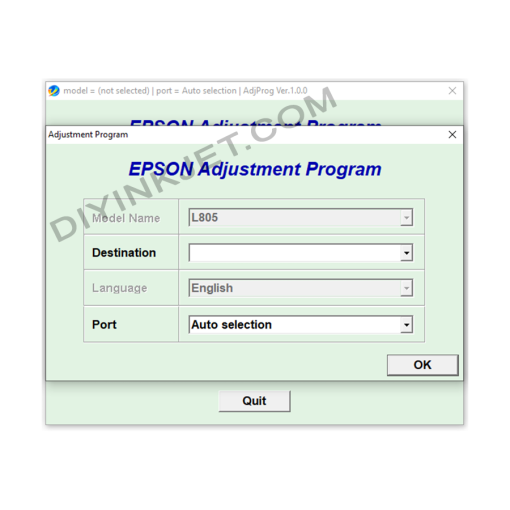

Epson L805 Adjustment Program

1 × 5 $

Epson L805 Adjustment Program

1 × 5 $ -

×

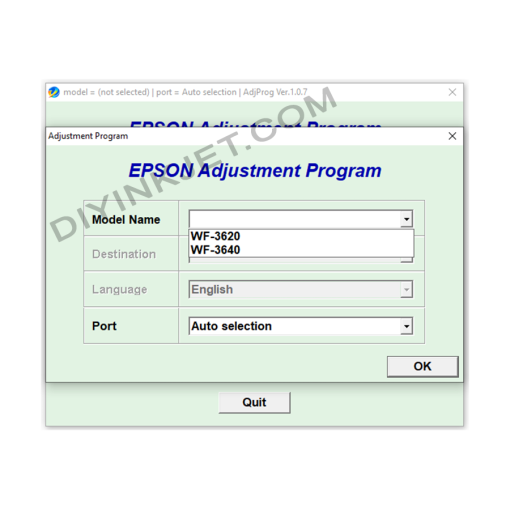

Epson WF-3620 WF-3640 Adjustment Program

1 × 5 $

Epson WF-3620 WF-3640 Adjustment Program

1 × 5 $ -

×

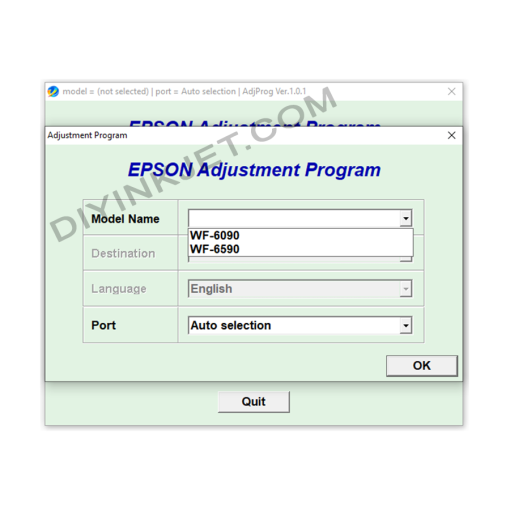

Epson WF-6090 WF-6590 Adjustment Program

1 × 5 $

Epson WF-6090 WF-6590 Adjustment Program

1 × 5 $ -

×

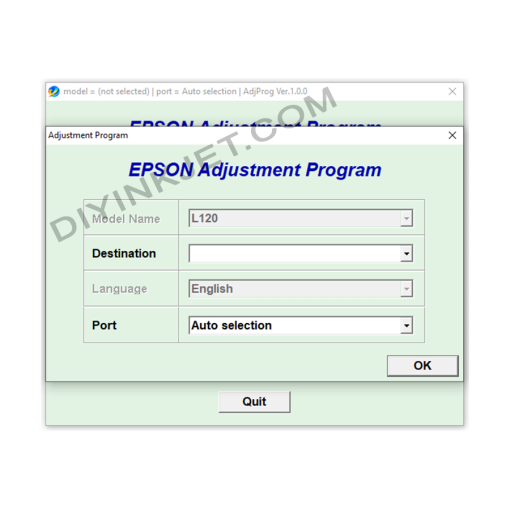

Epson L120 Adjustment Program

1 × 5 $

Epson L120 Adjustment Program

1 × 5 $ -

×

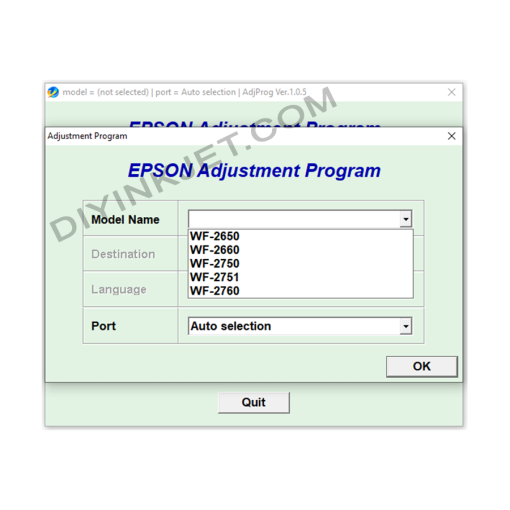

Epson WF-2650 WF-2660 WF-2750 WF-2751 WF-2760 Adjustment Program

1 × 5 $

Epson WF-2650 WF-2660 WF-2750 WF-2751 WF-2760 Adjustment Program

1 × 5 $ -

×

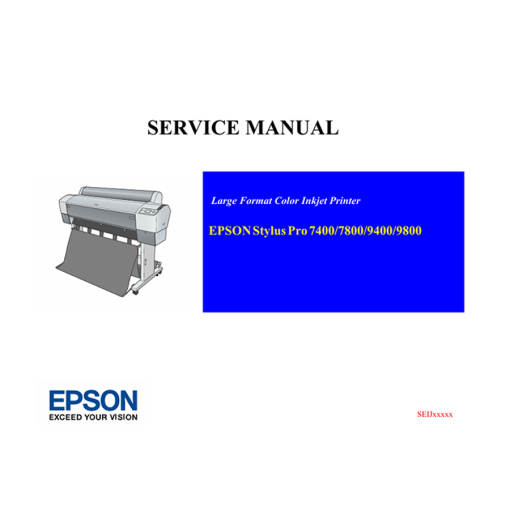

Epson Service Manual: The Ultimate Guide for DIY Printer Repair (Epson 7400, 7800, 9400, 9800 Series)

1 × 6 $

Epson Service Manual: The Ultimate Guide for DIY Printer Repair (Epson 7400, 7800, 9400, 9800 Series)

1 × 6 $

Subtotal: 86 $